The Importance of Hydrogen in Industrial Applications and the Role of Sensors

Introduction

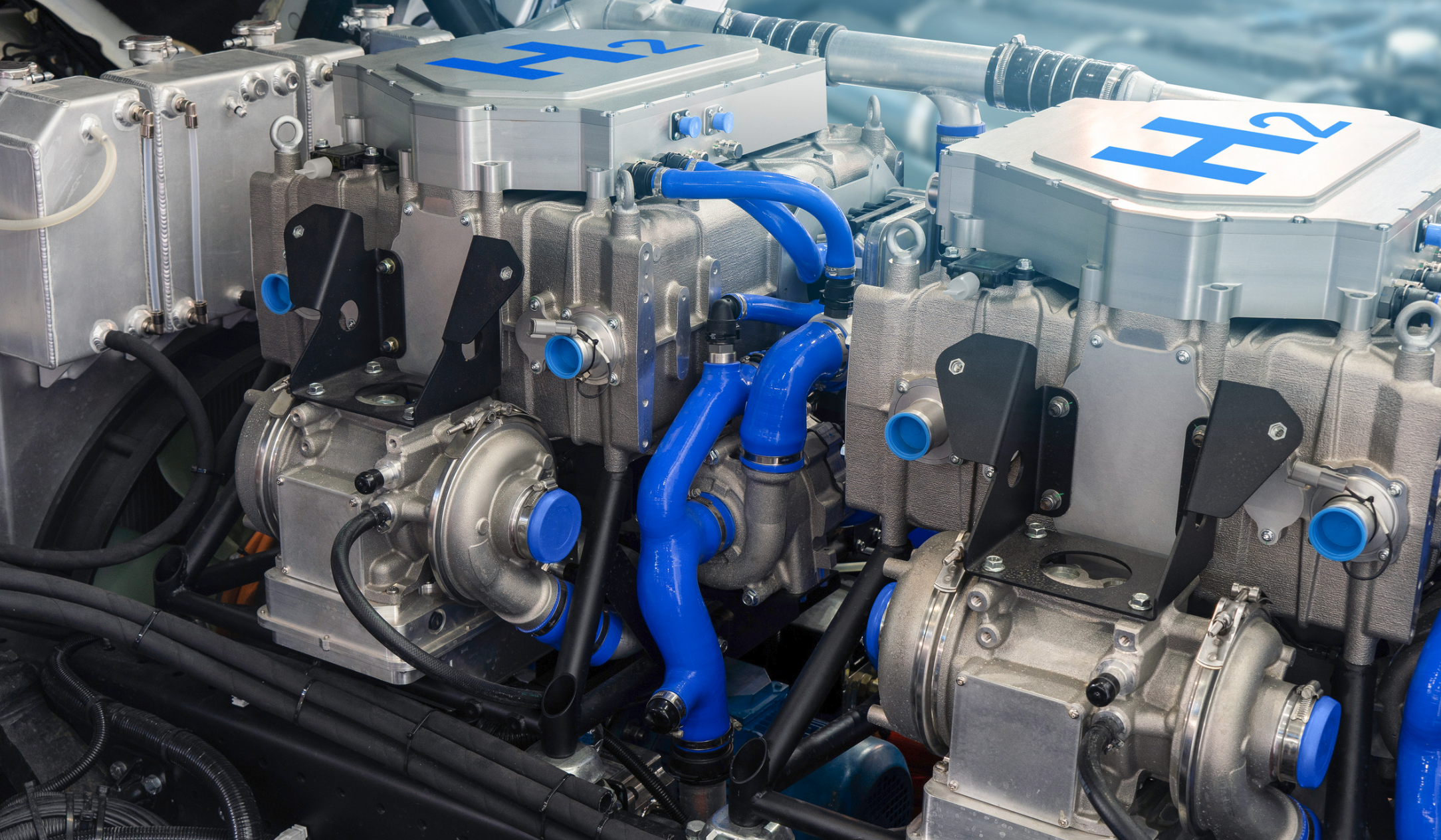

Hydrogen, a ubiquitous element in nature, holds significant potential for transforming industries, particularly those that are hard to abate, such as steel, cement, chemical manufacturing, and glass production. Utilizing hydrogen as a clean energy source can drastically reduce carbon emissions and enhance energy efficiency. However, to harness this potential effectively, the deployment of advanced sensors will be crucial.

The Importance of Hydrogen

- Clean Energy Source: Hydrogen can be produced from renewable energy sources, making it a sustainable and eco-friendly alternative to fossil fuels. When used in industrial processes, it generates zero emissions, thus contributing to the reduction of greenhouse gases.

- Versatility: Hydrogen can be utilized across various industrial sectors. In steel manufacturing, it can replace coal in the reduction process, significantly cutting down CO2 emissions. Similarly, in the chemical industry, hydrogen is a vital feedstock for producing ammonia and methanol, essential components for fertilizers and plastics.

- Energy Storage: Hydrogen serves as an efficient energy storage medium. Excess renewable energy can be converted into hydrogen through electrolysis and stored for later use, thus stabilizing energy supply and demand.

The Role of Sensors in Hydrogen Utilization

To efficiently integrate hydrogen into industrial processes, precise monitoring and control are essential. This is where sensors come into play.

- Leak Detection: Hydrogen is a highly flammable gas. Advanced sensors are necessary to detect even the smallest leaks in real-time, ensuring safety and preventing potential hazards.

- Gas Composition Analysis: Sensors capable of analyzing gas composition are crucial for maintaining the quality and efficiency of hydrogen production and utilization. Accurate measurements ensure that the hydrogen used in industrial processes meets the required purity standards.

- Process Optimization: Real-time data from sensors help in optimizing industrial processes. By monitoring variables such as pressure, temperature, and gas flow, industries can fine-tune their operations to maximize efficiency and minimize energy consumption.

- Compliance and Reporting: Regulatory compliance is a significant aspect of modern industrial operations. Sensors provide the necessary data to comply with environmental regulations and standards, ensuring that industries can report their emissions accurately.

Applications of Hydrogen in Industry

- Steel Manufacturing: The steel industry is one of the largest industrial emitters of CO2. Traditional steel production uses coke, derived from coal, to reduce iron ore into iron. By replacing coke with hydrogen in the reduction process, steel manufacturers can significantly reduce their carbon footprint. Hydrogen acts as a reducing agent, combining with oxygen in the ore to form water instead of CO2. This not only lowers emissions but also enhances the purity of the steel.

- Cement Production: Cement manufacturing is another major source of CO2 emissions, primarily due to the calcination of limestone and the combustion of fossil fuels. Hydrogen can be used as a clean fuel in cement kilns, replacing traditional fossil fuels. This substitution can drastically reduce emissions associated with cement production. Moreover, integrating hydrogen with carbon capture and utilization technologies can further minimize the environmental impact.

- Chemical Industry: In the chemical industry, hydrogen is a critical feedstock for producing ammonia and methanol. Ammonia is essential for fertilizers, while methanol is used in various chemical syntheses and as a fuel. By using green hydrogen, produced from renewable energy, the chemical industry can reduce its reliance on fossil fuels and lower its carbon emissions. Advanced sensors ensure the precise monitoring of hydrogen purity and process efficiency, enhancing overall productivity.

- Glass Production: The glass industry requires high temperatures for melting raw materials, traditionally achieved using fossil fuels. Hydrogen can serve as an alternative fuel, providing the necessary heat while reducing greenhouse gas emissions. Sensors play a crucial role in maintaining the optimal combustion conditions and monitoring emissions, ensuring compliance with environmental regulations.

Conclusion

Hydrogen has the potential to revolutionize industrial sectors that are traditionally hard to decarbonize. However, the successful integration of hydrogen into these processes hinges on the deployment of advanced sensors. These sensors will ensure safety, optimize processes, and help industries comply with environmental regulations. As the world moves towards a sustainable future, the role of hydrogen and the technology supporting its use will become increasingly vital.